In a fast-paced CNC environment, setup time is everything. The quicker you can swap fixtures and get back to cutting, the better your production output will be. If your shop handles mixed fixtures, you’ve likely experienced the headache of fixture changes that require re-indicating or re-adjusting each time.

Luckily, there’s a solution: the 8-hole master plate. This simple yet effective workholding system is revolutionizing how shops handle mixed fixtures. Here’s why.

What Is the 8-Hole Master Plate?

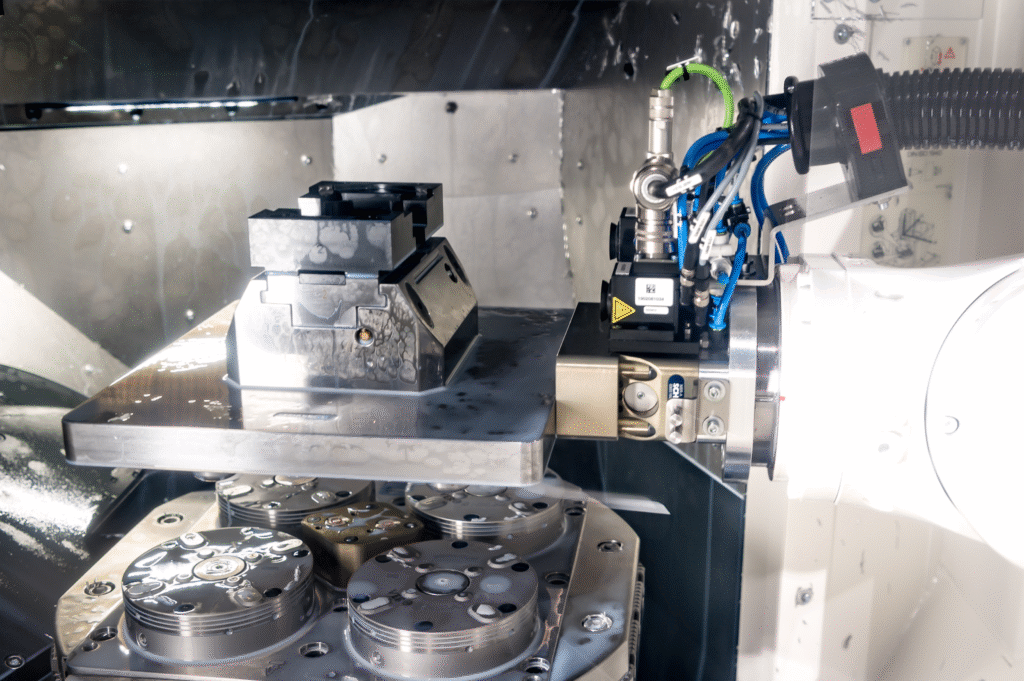

An 8-hole master plate is a manual quick-change system designed to streamline fixture changes. It allows you to switch between D52 vises, D96 chucks, and other custom fixtures with ease, all while maintaining precision and repeatability. This system features 52×52mm and 96×96mm locating holes to fit various fixture types.

The beauty of the 8-hole master plate lies in its hydraulic vise With this setup, you can use one base system for a variety of fixture types, making it easier and faster to switch between different setups.

How Does It Work?

Here’s how you can benefit from the 8-hole master plate in your shop:

- Mount the master plate on your CNC machine. Once it’s in place, it becomes a stable reference point for all your fixtures.

- Attach the fixtures (like D52 or D96 vises) to the plate using the standard locating holes.

- When it’s time to switch, swap fixtures quickly—the master plate ensures that everything aligns precisely and consistently every time.

The key advantage is that you don’t need to re-indicate or realign your fixture after each change. You simply dock your fixture onto the plate, and you’re good to go. This cuts down your setup time significantly and improves overall workflow efficiency.

Key Features of the 8-Hole Master Plate

- Dual locating patterns (52×52mm and 96×96mm): Allows you to use both small and large fixtures without changing the base system.

- High repetition accuracy: Ensures that your fixtures are precisely positioned each time, with 0.005mm repeatability.

- Up to 90% less setup time: Switching fixtures is quick and easy, which leads to higher productivity.

- 200kg bearing capacity: Can handle heavy fixtures without compromising accuracy or stability.

These features make it a 5th axis vise for shops that need to quickly change between different fixture types.

Who Benefits from the 8-Hole Master Plate?

This system is ideal for:

- Shops with high-mix production: If you frequently switch between different fixture types, the 8-hole master plate can save you time and effort.

- Low-to-medium volume shops: For shops with varied part runs, the 8-hole master plate helps you manage fixture changes without slowing down the process.

- Shops that need precision: With 0.005mm repeatability, the system ensures your setups are always accurate, no matter how often you change fixtures.

The Bottom Line

The 8-hole master plate is a simple yet effective solution for shops that handle mixed fixtures. It’s designed to reduce setup time, improve repeatability, and increase productivity. Whether you’re switching between different vises or chucks, the 8-hole master plate ensures that every fixture change is fast, accurate, and hassle-free.